Understanding Paddle Wheel Flow Meters: Applications and Benefits

Introduction Paddle Wheel Flow Meters

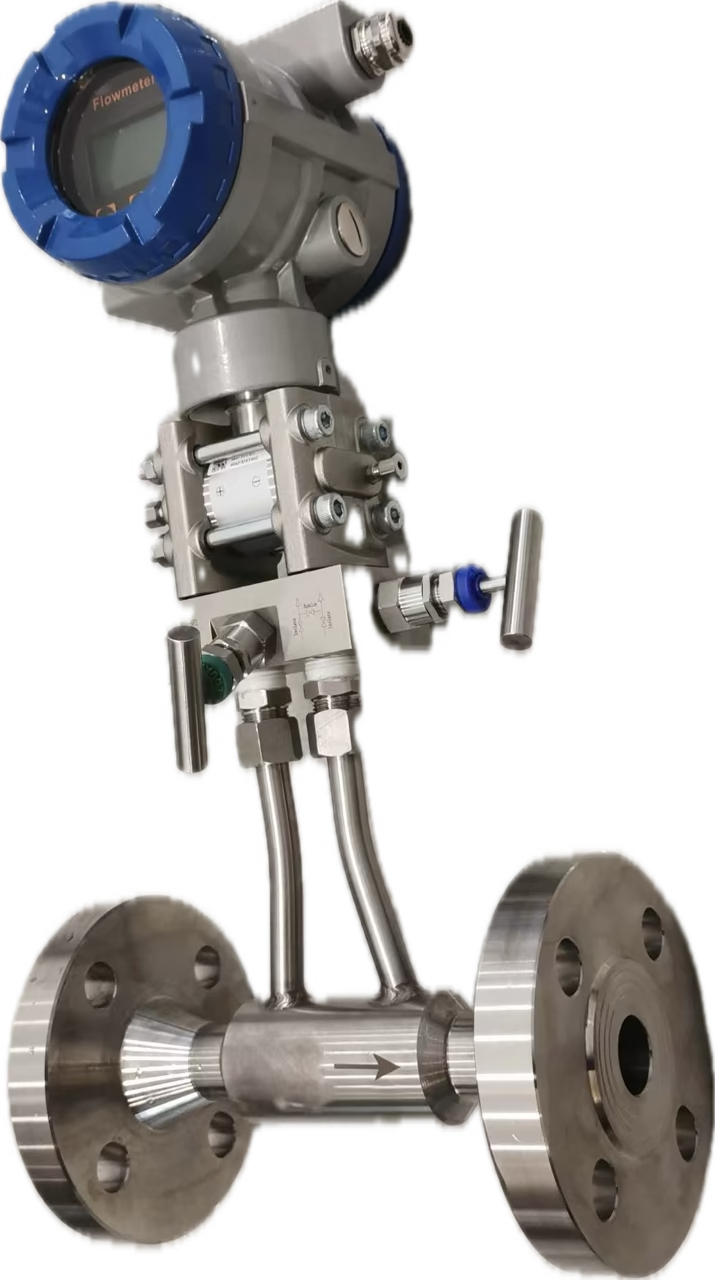

Paddle wheel flow meters widely utilized devices designed to measure the flow rates of various fluids in pipelines. The operational principle behind these flow meters hinges on a simple yet effective mechanism featuring a rotating paddle. This paddle, positioned perpendicular to the flow direction, spins as fluid passes through the measurement area. The rotational speed of the paddle is directly proportional to the velocity of the fluid, thereby allowing for accurate flow measurement. This technology offers a reliable solution for applications in numerous industries, including water treatment, chemical processing, and HVAC systems.

The design of paddle wheel flow meters includes several key components that contribute to their functionality. A cylindrical body houses the paddle and ensures that fluid flows smoothly over it. As the paddle rotates, it sends signals to the flow meter’s electronic system, which processes the data and displays the flow rate. This process makes paddle wheel flow meters highly responsive and capable of providing real-time flow measurements, crucial for system monitoring and process control.

paddle wheel flow meters suitability

Paddle wheel flow meters are particularly suitable for measuring clean, low-viscosity liquids. They are adept at measuring water, chemicals, and a range of other non-viscous fluids, thanks to their capacity to accommodate a variety of pipeline sizes and configurations. However, they may not perform well with fluids containing high levels of solids or viscosity, which could hinder the accurate rotation of the paddle. Compared to other flow measurement technologies, paddle wheel meters often provide a cost-effective solution, offering good accuracy with minimal maintenance requirements. Their straightforward design and easy installation further contribute to their appeal in flow measurement applications.

Key Advantages of Paddle Wheel Flow Meters

Paddle wheel flow meters have gained significant popularity across various industries due to their remarkable advantages. One of the primary benefits is accuracy. These devices utilize a rotating paddle to measure flow speed, which translates to precise flow rate readings. This level of accuracy is essential for applications where quantifying fluid movement directly affects operational efficiency and product quality. Industries ranging from water treatment to food processing rely on the precision offered by paddle wheel technology, making them an invaluable tool.

Another notable benefit is cost-effectiveness. Paddle wheel flow meters are typically less expensive than other flow measurement technologies, making them an attractive choice for businesses looking to manage budgets without compromising on quality. The initial investment often offset by their reliable performance and longevity, as these devices usually have lower total costs of ownership over time.

Installation and maintenance

Installation and maintenance are additional factors where paddle wheel flow meters excel. Their compact design allows for straightforward installation in various piping configurations, without the need for elaborate fittings or modifications. This ease of installation reduces labor costs and downtime during implementation. Furthermore, paddle wheel meters designed to have low maintenance requirements, as they generally lack intricate mechanical components that often necessitate regular upkeep. This characteristic promotes prolonged service life and operational reliability.

Adaptability is another significant advantage. Paddle wheel flow meters utilized in different environments and are compatible with a wide range of fluids, including water, oil, and various chemicals. This versatility makes them suitable for applications in industries like agriculture, HVAC, and chemical processing. The ability to perform well across scenarios enhances their appeal as a fluid measurement solution, ensuring accurate and consistent performance regardless of the specific conditions.

Applications of Paddle Wheel Flow Meters

Paddle wheel flow meter’s widely utilized across various industries, owing to their versatility and reliability in measuring fluid flow rates. One of the primary applications is in water treatment facilities, where these meters help monitor the flow of treated water, ensuring compliance with regulatory standards. Their accuracy in detecting variations in water flow is crucial for maintaining optimal treatment processes, thereby reducing waste and enhancing efficiency.

application at food and beverage industry

paddle wheel flow meters play an essential role in ensuring product quality and consistency. For instance, paddle wheel flow meter employed in liquid processing applications, such as monitoring the flow of milk in dairy plants or measuring the liquid ingredients in breweries. Their ability to provide real-time flow data allows manufacturers to make informed decisions, improving both production efficiency and product quality while also adhering to hygiene standards.

The HVAC sector also benefits significantly from the use of paddle wheel flow meters. In this context, they are integral to monitoring and controlling the flow of chilled or heated water in HVAC systems. Maintaining the correct flow rate is vital for energy efficiency and for ensuring a comfortable environment in residential and commercial buildings. By accurately measuring flow rates, HVAC operators can optimize system performance and reduce operational costs.

Application at chemical processing industries

paddle wheel flow meters are critical for accurate dosing and mixing of various chemicals. They facilitate the monitoring of flow rates in processes like batch production or continuous operation, thus helping manufacturers avoid costly errors due to imprecise measurements. In residential settings, these flow meters employed in irrigation systems or residential water supply monitoring, ensuring effective resource management.

Overall, the versatility of paddle wheel flow meters across these applications showcases their significance in enhancing operational efficiency and ensuring accurate flow measurement across diverse sectors.

Installation of paddle wheel flow meter,

Proper installation and maintenance of paddle wheel flow meters are crucial for achieving optimal performance and ensuring accurate flow measurement. During installation, several key considerations addressed, including positioning, orientation, and flow direction. The paddle wheel flow meter should be installed in a location where the flow is fully developed and free from turbulence. This typically means positioning the meter at a distance of five to ten pipe diameters from any upstream fittings, valves, or bends. Correct orientation is also vital; the flow meter should be installed in a horizontal position with the paddle wheel shaft parallel to the ground, which helps prevent sediment buildup and ensures proper operation.

Maintenance of paddle wheel flow meter

Maintaining paddle wheel flow meters requires periodic checks and routine cleaning. A recommended maintenance schedule could include monthly inspections, where users should verify the integrity of the device and check for any signs of wear or damage. Cleaning the sensor and surrounding components is essential, particularly in applications where sediment or debris is common. The cleaning schedule may vary based on the application’s specific environmental conditions and operational demands. Regular calibration is another important aspect of maintenance. This process should be conducted at least annually or after any significant changes in the system that might affect flow characteristics.

To maximize the accuracy and lifespan of paddle wheel flow meters, adopting best practices is essential. These practices include attentive monitoring of readings, ensuring the flow remains within the operational range outlined by the manufacturer, and promptly addressing any anomalies in the data. Implementing troubleshooting measures and keeping accurate maintenance records will further enhance the longevity of paddle wheel flow meters. By adhering to these guidelines, users can ensure that their flow meters not only operate efficiently but also provide reliable data for optimal decision-making in various applications.