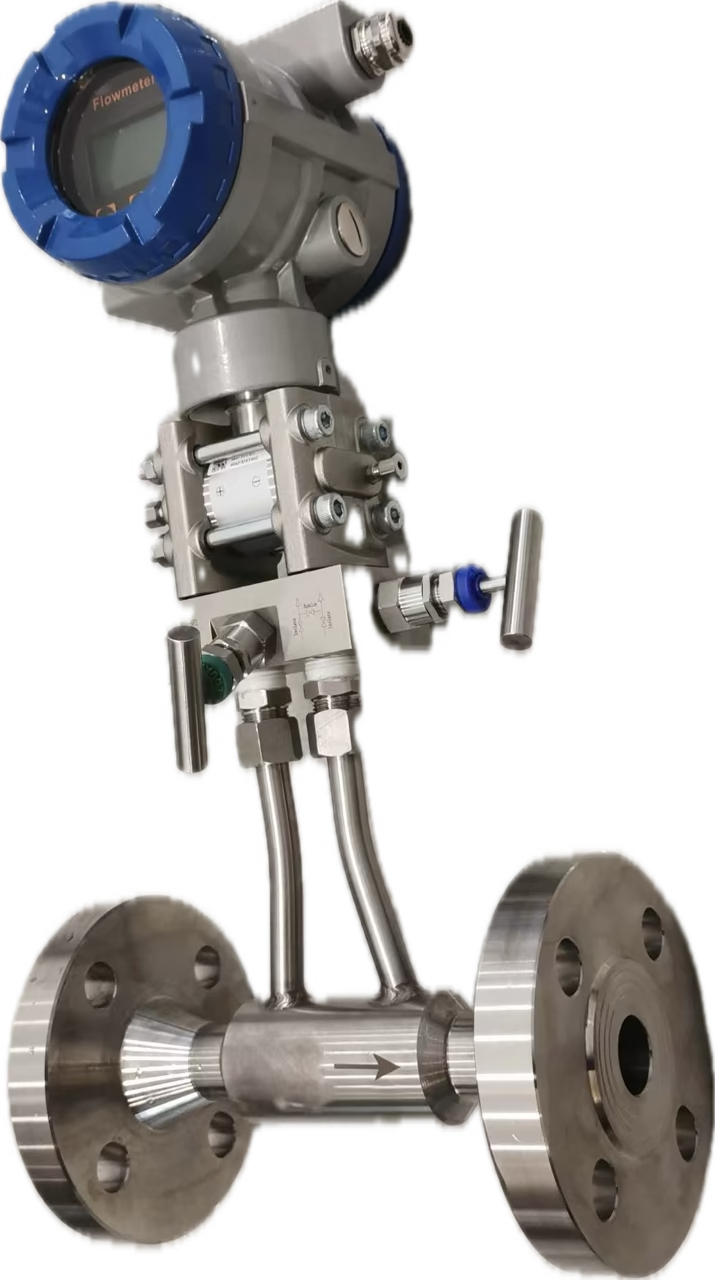

Understanding Orifice Flow Meter

An orifice flow meter, device used to measure the flow rate of liquids and gases. It operates on the principle of differential pressure. The flow rate determined by the pressure drop across a restriction, known as the orifice plate. This technology widely adopted in various industries for its reliability and precision when measuring with an orifice flow meter.

Applications of Orifice Flow Meters

Orifice flow meters are predominantly used in industries such as oil and gas, water treatment, and chemical processing. Their simple design allows for easy installation and maintenance. This makes them an economical choice for measuring flow in pipelines using an orifice plate. Facilities often utilize these meters for monitoring flow rates in processes, which is critical for regulatory compliance and safety.

Advantages and Disadvantages

One of the primary advantages of orifice flow meters is their cost-effectiveness and long-term reliability. They boast an accuracy range of about ±1% to ±3% of the reading, depending on the installation and calibration. However, they also come with disadvantages such as reduced accuracy at low flow rates and the potential for wear over time due to erosion. Understanding both aspects helps industries decide when to use these devices based on their specific needs for an orifice flow meter.

In conclusion, they serve as a crucial tool in flow measurement. This supported by their advantages in varied applications. Despite minor drawbacks that can affect their accuracy in certain situations, their benefits often outweigh the negatives. This makes orifice flow meters a trustworthy choice in the realm of fluid mechanics.

Leave a Reply